Gason Planters are designed by experts and built with high quality materials to ensure our machines deliver superior in-field performance and stand the test of time.

We understand that every farm is different, and our range of optional extras are designed to maximise efficiency and planting performance.

Our tillage planter bars provide exceptional trash clearance with straight edges on tines and clean underframe design with no tine towers or springs fitted below the

Only the best quality hydraulic components are used for precise control and reduced maintenance. Heavy duty, hardened and molycoated pins and bushes minimise wear and maintain wing hinge

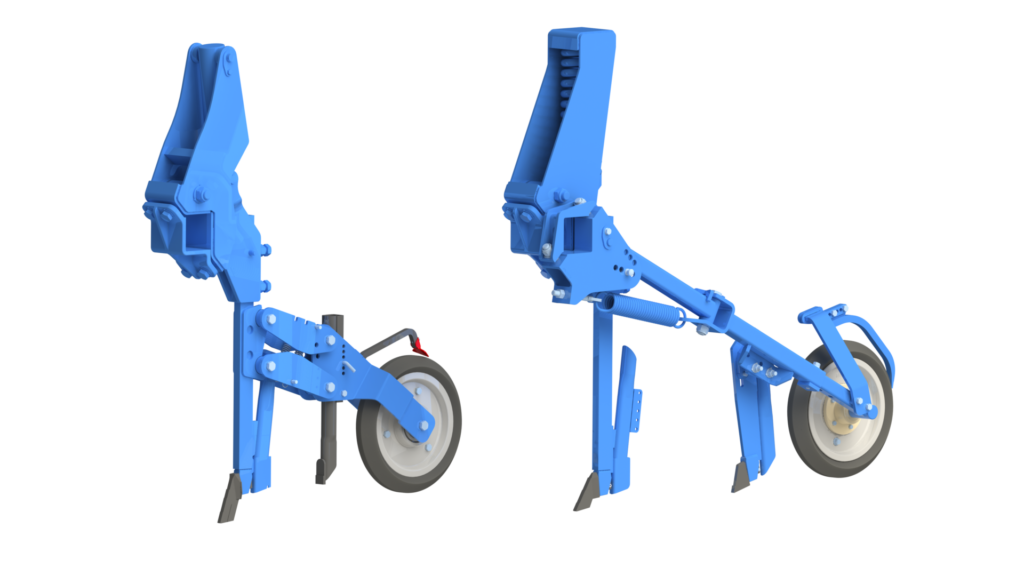

Rigid pull is the ideal choice for flat paddocks because considerable weight is transferred to the tractor drawbar improving traction. Available with hydraulic hitch height

Gason’s tried and proven tine assemblies are used on both NT and T Series planter

ScariTILL spring tines utilise frame mounted

HydraTILL hydraulic tines utilise Gason’s parallelogram presswheel

Gason’s new Rear Presswheel design delivers supreme performance in the paddock, while protecting your back

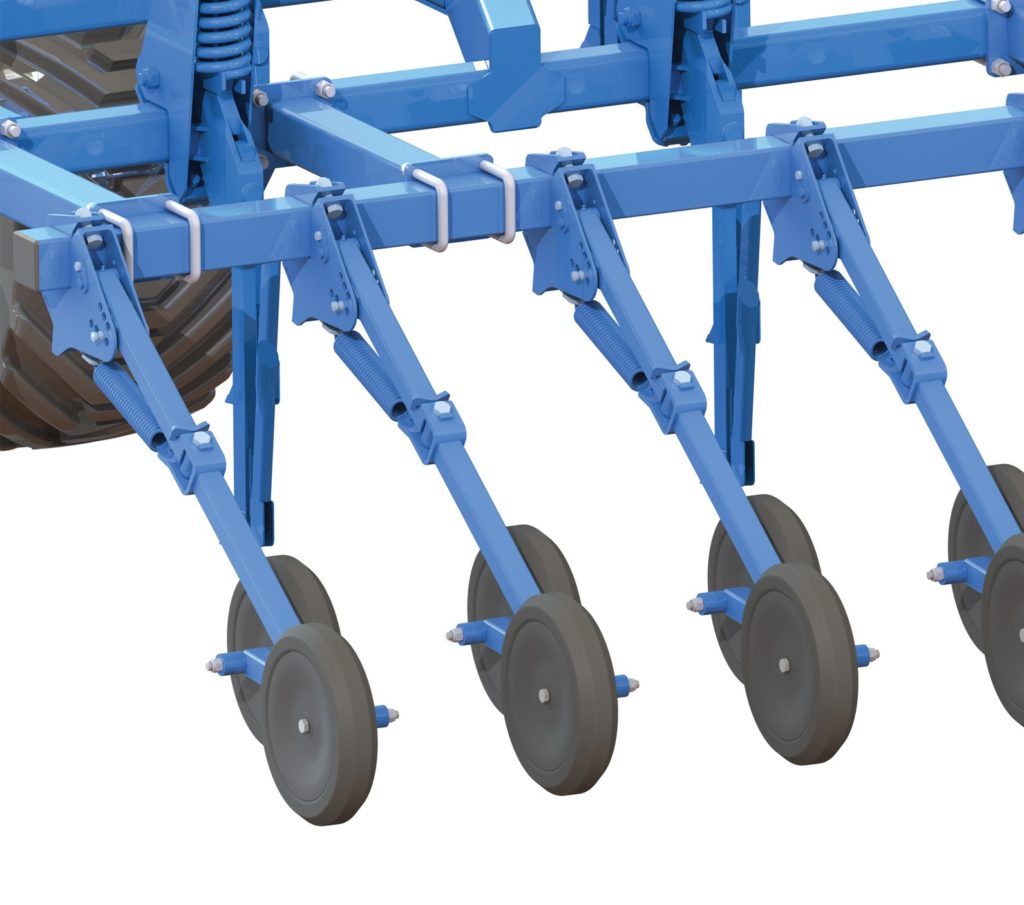

With improved trash flow inside the planter frame, superior reliability in dusty conditions and our most cost effective option available, the new Gason Rear Presswheels are designed for the harshest

Press wheels help to increase soil-to-seed contact which can improve germination rates and soil moisture utilisation. Available in parallelogram tine mounted (Hydraulic tine only) or frame mounted for row spacings above

Sowing boots can be mounted on the press wheel arm for better seed depth control, and optionalmud scrapers are available to stop build up in sticky

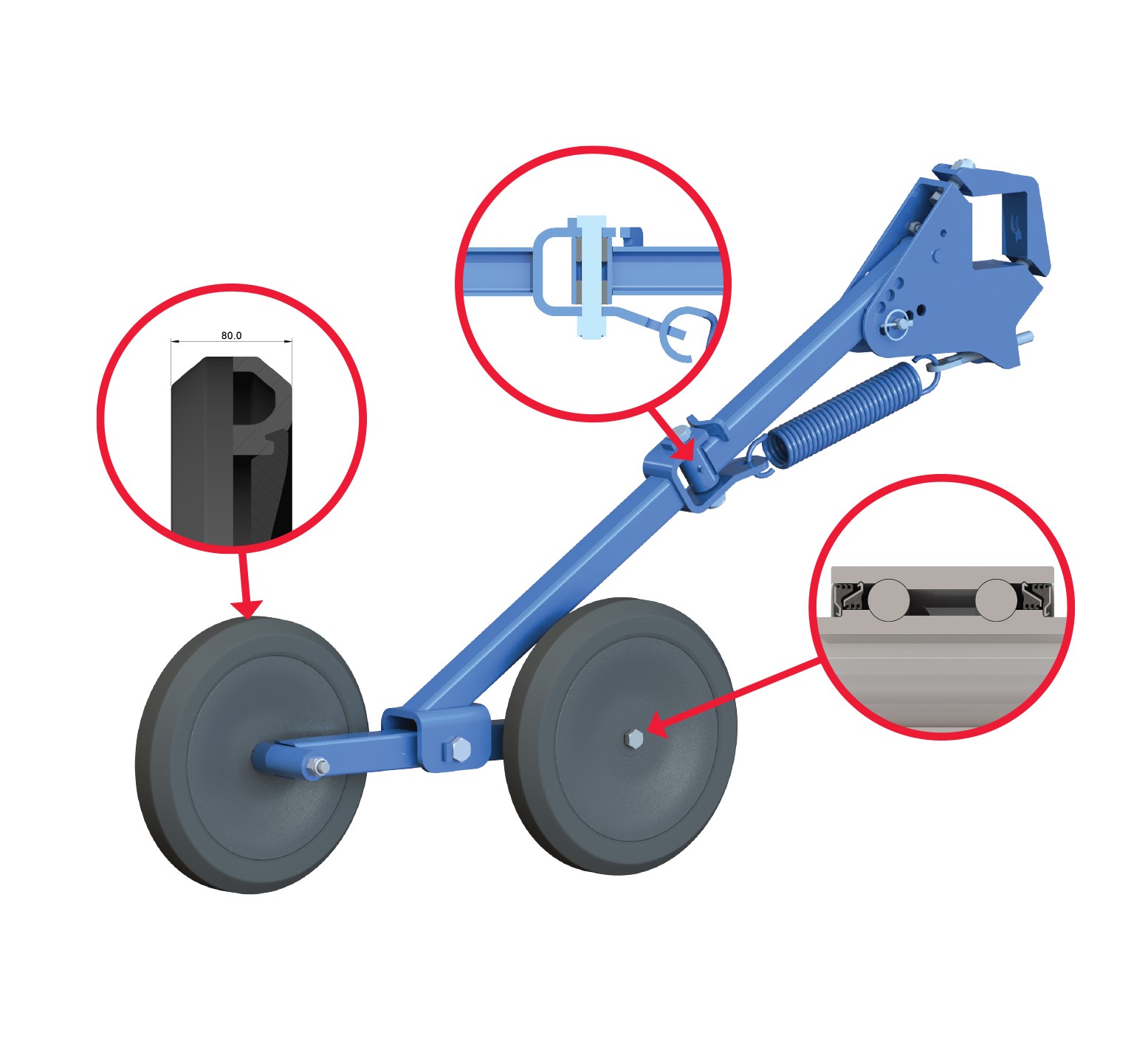

Our new design features:

• OTICO FARMFLEX® presswheel assemblies

• 80mm wide wedge-shaped semi-pneumatic tyres provide a firm seed bed and good mud shedding

• PEER® dual row angular contact bearings specifically designed for tillage applications, with six sealing lips at each end for superior reliability in dusty conditions

• All pivots use two hardened steel bushes with a grease reservoir between and pins that are either hardened steel or CL 12.9 bolts

• Double walking-beam presswheels can be set at 176mm (7”), 200mm (8”) and 250mm (10”) spacings

• Adjustable down-force up to 24kg per wheel

• Toolbar kits available for Gason planters (not compatible with rear tow seeders)

• Single wheel assembly available for odd tine